Homebrew Bottle

Conditioning might seem kind of unimportant for many, but it is the opposite. Conditioning is how you let your beer be carbonated, and it can change the final outcome of the brewing process.

Carbonation changes how your beer feels in your mouth. It can mute flavors and help your beer to build new tastes when ageing. Conditioning is the cherry on top of the brewing process. Without bottle conditioning, beer results flat.

While the primary fermentation is happening, the yeast consumes sugars to generate alcohol and CO2, which is permitted to escape.

Ales are usually ready to bottle in 2-3 weeks when fermentation has completely finished. There should be few, if any, bubbles coming through the airlock. Although 2-3 weeks may seem like a long time to wait, the flavor won't improve by bottling any earlier. Amazon's Choice for homebrew bottles. 16 oz Amber Glass Beer Bottles for Home Brewing 12 Pack with Flip Caps. 4.7 out of 5 stars 480. Mar 23, 2018 How to bottle homebrew. I look at bottling as four distinct phases: Cleaning bottles. Clean bottles = clean beer. Your bottles must be scrupulously clean of any residue before bottling. If you are removing your labels, this is the first step. I recommend you do – it’ll add to the charm when sharing with.

To reach an excellent and appropriate level of carbonation, brewers must look to create higher pressures than the ones they have after primary fermentation.

Keep in mind that 5 gallons of homebrew beer will require at least 54 of the standard 12 ounce beer bottles. This can be a lengthy process during the bottling and if you have a kit that is even larger than that for you brew regularly, you may want to consider getting some professional bottling tools. (1) 1 product ratings - Beer Bottle Capper Ferrari Red Baron Emily for Home brew bottling Crown Cap New.

Bottle conditioning in large industries

A lot of big breweries use a method called forced carbonation. This process it’s known for being reliable, easy and fast. It consists of forcing CO2 pressure into a tank until it dissolves in the beer.

Large companies inject CO2 directly into the beer after fermentation. It occurs during or after the bottling process, and it skips the need to wait for a long time until CO2 generates naturally. This gas dissolves into the beverage.

With this method, the brew can be out in hours and not weeks. That is why it is so convenient for a big company to use this quick method. For this method to be successful, the company will make sure the temperature is right. The lower the heat, the faster the CO2 dissolves into the brew.

This is pretty much a reversed process; it’s sending CO2 gas down into the batch, and this gas will begin to rise from the bottom and dissolve into the brew. Big breweries push the gas up from the bottom because doing it like this it increases efficiency and it speeds up carbonation.

This method has a few drawbacks. It can increase the risk of over-carbonation, and the extra pressure also increases the risk of CO2 leaks.

A better method if you want to make the best beer you can is bottle conditioning. It is quite different from the fast and accelerated process of forced carbonation, but bottle conditioning has better results.

Yes, bottle conditioning can seem complicated and time-consuming, but it is worth it. Bottle conditioned beer translates in a longer shelf life. Also, beers that go through bottle conditioning continue to develop and grow in complexity over time thanks to the secondary fermentation.

What NOT to do for successful bottle conditioning.

Bottle conditioning adds a unique effect on the beer. When the beer goes into bottles and priming sugar is added, you are reintroducing the elements and starting the fermentation process again.

This way, the yeast goes through the same process; it starts consuming sugar and producing alcohol and CO2. This process also introduces new flavors that otherwise will not be present.

Bottle conditioning is not a complicated process, but it is easy to make mistakes.

Avoid overfeeding your yeast during bottle conditioning; you can cause messy explosions if you are not careful. Pay attention to the amount of priming sugar you use, and make sure it isn’t too much for the volume of your beer.

Giving your yeast too much sugar to process in the bottle is one of the easiest ways to end up with a bottle bomb. You can use a priming calculator to avoid this mistake.

Another way to mess up the process is by not mixing the priming sugar correctly after adding it to the beer. If you don’t mix it well, it won’t be distributed evenly.

This can lead to some bottles exploding and some ending up flat. Make sure you combine your priming sugar without oxygenating it. If you don’t want to take the risk by yourself, you can use a priming tab.

This other mistake can be easily committed at every stage of brewing and not only conditioning; it’s bacterial infection. If you didn’t sanitize all your tools and equipment correctly, you will end up with a bacterial infection in your brew, and this is known to cause explosions, too.

You need to take a look at every step you make and make sure everything is clean. Ensure that you are practicing the best sanitation methods at each and every single one of the stages of brewing. If your beer is infected, it is lost.

Another common mistake is bottling your beer before it is finished fermenting; this is an easy way to guaranteed a bottle bomb. To avoid this, use a hydrometer and monitor that you reach final gravity before you start bottling.

Final gravity can be seen once a specific gravity shows no changes for 2 or more days of monitoring. If you don’t have a hydrometer, just make sure to give your beer more time to ferment than necessary to ensure that the process is finished.

You can also make mistakes while trying out a new yeast. You want to make some subtle changes to your beer. If the yeast has a much higher attenuation rate than your primary yeast, it will be a problem. This way, you end up starting more fermentation inside the bottle than what you needed and cause an explosion.

When adding a different yeast, it may change the amount of priming sugar you’ll need for carbonation and creates high pressure inside. This dooms your bottles to explode.

If you have an explosive bottle, but you haven’t committed any of the mistakes above, take a look at the bottles.

Not all bottles are built equally, and beer bottles are designed to hold the pressure that carbonation creates. If you are not using bottles designed for this, you will face the risk of the bottle giving up to the pressure. Also, make sure that if you are reusing a container that it is intended for reuse.

If you already have some bottles explosions going around but want to save the rest, you probably can still save some of them.

You should use pasteurization if you are afraid your bottle will be over carbonated. Heat up some water to make the yeast die and stick your bottles in water long enough to kill it. It will quickly stop further fermentation from happening. If your bottles are already exploding, it is too late to do this; it can actually be more dangerous.

You can also slightly open the cap of your bottle to allow some gas to escape and then reseal your bottle. It is great if you are using pry-off caps. You can apply this saving method every few hours or days; it depends on the amount of extra carbonation you are looking to release.

Another way to save your brew is by lowering the temperature of the yeast. If it is cold enough, it will hibernate. This can stop the fermentation in your bottles and prevent the pressure from increasing. If you think your beer is over-carbonated, release the gas before doing this.

Conditioning your own bottles

When it comes to bottle conditioning, you don’t want to be lazy about it. If you make a mistake, you will end up with a damaged batch or bottle bombs.

You first need to determine your beer volume:

- How much are you making?

- How much are you fermenting?

Keep in mind what you need will be a little less than the amount you have in the fermenter because you will end up losing a little in the transfer.

You also need to determine your beer temperature. The colder it is, the more CO2 is in suspension. Make sure you know your desired CO2 level. If you don’t know, 2.25 is a good measure.

Many beers also have traditional standards that you can follow. Otherwise, you can go on your own if you want. Think of CO2 as an ingredient, not just something that is happening around.

You need to decide where you are going to get your priming sugar. Corn sugar is the standard. You can also use honey, brown sugar, or maple syrup—almost anything with simple sugars.

When you choose, keep in mind that the priming sugar that you’ll use will affect your final flavor. Put all the information into a priming sugar calculator. Do this to make sure you are doing it right and not adding too much or too little to your beer.

Make sure you weight your sugar and mix it with a cup or two of water. Once boiling, add it to the bucket or bottles.

That is it for consistent bottle conditioning.

Remember to keep your bottles warm to have faster and better results.

- Inspect Your Bottles

One tip for making sure you always deliver proper bottle conditioning is to inspect your bottles. You can do this to each bottle by holding it up in front of a window or light and looking at it. Look for cracks or chips around the mouth or bottom and check for mold or other debris at the very bottom too. If everything looks good, use it.

- Remove the labels from the bottle.

You can help yourself with ammonia; make sure you use it in a ventilated area. Soak the recycled bottles in a mix of water and ammonia, and after soaking, remove it gently.

- Get a Bottle Brush

You will also need to use a bottle brush. Remember the importance of sanitization in this whole process. If you let bacteria in, it will ruin your batch and even make your bottles explode if you are not careful.

Remember to Take the Right Precautions

- Don’t Attempt to Bottle Directly

A great tip is to never bottle directly from the fermenter. The better option is to siphon your beer off the fermenter and into a temporary priming bucket or carboy. Be careful with the splashing, mainly because air can quickly oxidize your finished product.

- Mixing is Important

For even better results, mix the priming sugar while the beer is on the priming bucket. This way, you can reduce the sediment in your finished bottles.

- Use the right fining agents

You need to use fining agents to clarify your beer and at the same time reduce sediment in the finish bottles. The fining agents need to be added before bottling. You can use additives like gelatin and polyclad, and these should be added after active fermentation.

- Weigh it Right

One more time, make sure you weigh your priming sugar. Avoid the old habit of just adding some corn sugar to your beer and that’s it. Sugar varies a lot; a cup of corn sugar is not the same as a cup of brown sugar. Use a priming sugar calculator for best results.

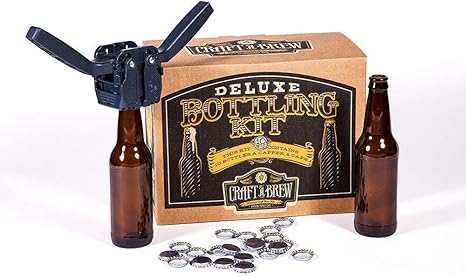

- Buy a Bottle Capper that Works

One investment that you should do is to purchase a quality bottle capper. This is a piece of essential advice; if you have ever used one, you know how it is.

You can use oxygen-absorbing bottle caps. They are popular, but that doesn’t mean that you need them. So don’t go buying everything you hear is a must.

- The carbonation is important

Bottles need the correct amount of headspace at the top to let carbonation take place and have proper pressure. If you are using a wand bottle filler, you can fill the bottles close to the top before removing it. Make sure you leave the space for the carbonation to happen anyway.

- Don’t Forget the Storage

One last advice, store your bottles correctly. After capping them, store them at fermentation temperature for 2 weeks to allow the fermentation of the priming sugar. After this, you can place them in a cool space away from light. Read: Bottling vs. Kegging

What do you need to condition your bottles?

First, they need to be clean. Check this simple tip out to save yourself hours of clean batches of bottles:

At this point, you already have all your brewing equipment to make sure your brew is ready for conditioning. You will need a carboy or bottles to let the secondary fermentation happen.

Buy Beer Bottles

If you are going to use bottles, make sure you are buying beer bottles. these are specially made to hold the pressure of carbonation. If you pick any random bottle, you may end up with a bomb bottle, because it will just crack thanks to the force.

Homebrew Bottle Labels

Get a Glass Carboy

If you are going to use a carboy for the secondary fermentation, I highly recommend a glass carboy over a plastic one or a fermentation bucket. A glass carboy it’s easier to clean and keep sanitized. It can last for years without breaking and scratching.

Did you forget the Siphon?

You will also need a siphon. With it, you can transfer your brew from your primary fermenter to the bottles or carboy without any problems or significant oxidation.

Priming Sugar

When it comes to bottle conditioning, priming sugar is an outstanding choice, you need to pick the one that you would like to add taste to your brew.

Table sugar is the basic type of priming sugar, it is low cost and easy to obtain. This sugar doesn’t add any flavor to the beer, which can be useful and makes it versatile. You can also use corn sugar; like table sugar, this one does not influence the taste.

Corn sugar has the advantage of being higher quality, and it is more reliable. You can obtain corn sugar in packages made for bottle carbonating, so you won’t have a hard time measuring the right amount.

If you are looking for that extra flavor, you should try honey. The feeling will change depending on the character of the syrup: the stronger it is, the stronger will taste on the beer.

Also, syrups can be used for priming, like maple syrup and molasses. Darker sugars will produce a more noticeable aftertaste and work great with more substantial and darker beers. Honey could be used for a light beer like a Kolsch, while maple syrup is perfect for a holiday type of ale.

Using the syrup as a primer can be challenging because the gravity of honey is different in every jar, and there is no concentration standard to work with. To use honey or syrup correctly, you need to use a hydrometer and measure the gravity.

You can even use watermelon juice. Add some to make a good and refreshing summer beer. Experiment a little that is what brewing at home is all about.

You will also need some extra yeast. Make sure that you are using the same yeast or one similar to the first you used during the primary fermentation. Drivers precise biometrics.

You don’t want the different yeast to cause a reaction inside your bottles and cause them to explode.

You will also need the space where you will store your bottles for the whole conditioning process, pick a warm place for better results.

Today I’d like to announce Homebrew 3.0.0. The most significant changes since 2.7.0 are official Apple Silicon support and a new bottle format in formulae.

Home Brew Bottles

Major changes and deprecations since 2.7.0:

- Apple Silicon is now officially supported for installations in

/opt/homebrew. formulae.brew.sh formula pages indicate for which platforms bottles (binary packages) are provided and therefore whether they are supported by Homebrew. Homebrew doesn’t (yet) provide bottles for all packages on Apple Silicon that we do on Intel x86_64 but we welcome your help in doing so. Rosetta 2 on Apple Silicon still provides support for Intel x86_64 in/usr/local. brew bottleandbottle doblocks use a new syntax format (one:cellarper platform).brew style --fixwill autocorrect formulae to this new format. This will allow more bottles to be relocatable.- The new

HOMEBREW_BOOTSNAPenvironment variable allows the use of the Bootsnap gem to speed up repeatedbrewcalls. This does not work (yet) on Apple Silicon or using Homebrew’s portable Ruby. - Bash, fish and zsh completions are generated automatically from the

CLI::ParserDSL. This will ensure they are kept up-to-date.

Homebrew Bottle Cleaner

Other changes since 2.7.0 I’d like to highlight are the following:

Finally:

- Discourse was made read-only on January 1st 2021 in favour of GitHub Discussions.

- Homebrew accepts donations through GitHub Sponsors and still accepts donations through Patreon. If you can afford it, please consider donating. If you’d rather not use GitHub Sponsors or Patreon (our preferred donation methods), check out the other ways to donate in our README.

Homebrew Bottle Label

Thanks to all our hard-working maintainers, contributors, sponsors and supporters for getting us this far. Particular thanks on Homebrew 3.0.0 go to MacStadium and Apple for providing us with a lot of Apple Silicon hardware and Cassidy from Apple for helping us in many ways with this migration. Enjoy using Homebrew!